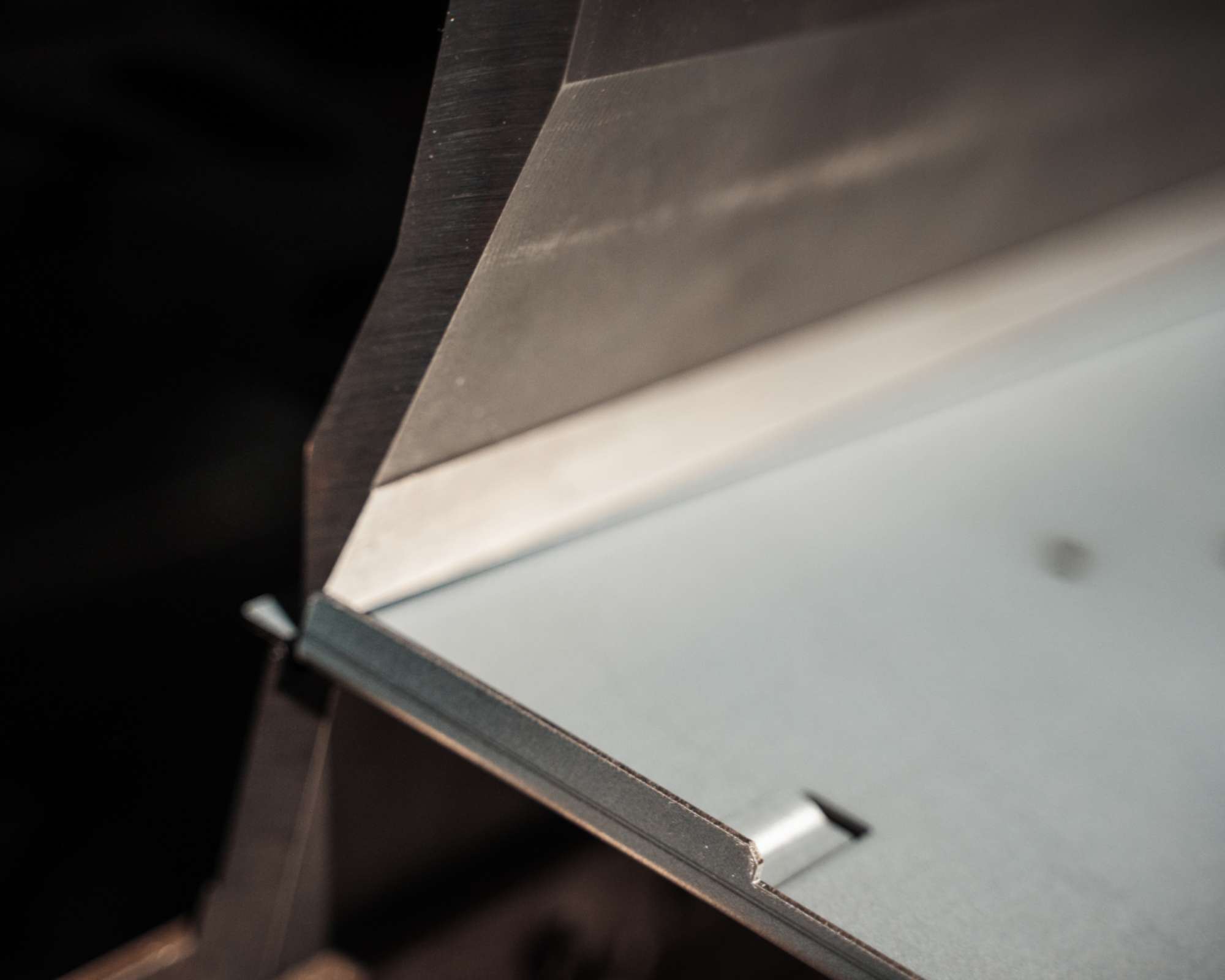

Sheet metal processing

We manage the entire sheet metal production process with the most modern technologies.

We process stainless steel, carbon steel, and pre-treated steel sheets, as well as aluminum, copper, and brass alloys (thicknesses from 0.5 mm to 8 mm).

Cutting.

We combine cutting machines, CO2 laser punches, and fiber to maximize the potential of both technologies.

Bending.

Our departments are equipped with both manual and robotic press brakes, allowing us to manage any type of sheet metal bending.

Surface finishing.

Aiming for effective removal of machining residues and excellent aesthetic uniformity, we use various methods: mechanical satin finishing, deburring, and sandblasting.

Fastener application.

For applying electronics fastening points to sheet metal parts, we use manual and automatic load presses with PEM fasteners, as well as rivet application technologies for pulling and deformation.

We manage sheet metal processing internally using a proven method.

We protect your electronics.

The results always meet your expectations because they come from the winning combination of advanced machinery and the skilled expertise of our operators.

More than a mascot: Mecky is a practical example of our production capabilities.

“With such mechanical armor, it’s impossible to go unnoticed!”

This is who I am…

Face in 5005 aluminum alloy

My face is made from 5005 aluminum alloy sheet, carefully shaped to give me a unique expression. This material is incredibly versatile and durable, ideal for natural oxidation treatment, which protects the surface from corrosion. I’m not only handsome but also ready to tackle any challenge with a touch of character!

Torso in DC01 steel with white electrolytic zinc coating

DC01 steel was chosen for its exceptional workability and ductility, enabling precise shaping of my mechanical armor. A bath in an electrolytic solution with zinc salts, followed by passivation, protects my surface from corrosion and gives me a refined look.

Arms in 5005 aluminum alloy sheet

My arms originate in the sheet metal processing department and are made from 5005 aluminum alloy, which contains 0.6% magnesium. This makes it perfect for treatments like natural oxidation, which creates a super-protective oxide layer on my "skin." The result? I’m always ready for action, unafraid of corrosion!

Legs in 5005 aluminum alloy sheet

My legs are made from 5005 aluminum alloy sheet, known for its balance of lightness and strength. Containing 0.6% magnesium, this alloy is ideal for surface treatments like natural oxidation, which protects against corrosion and ensures durability. Carefully processed in the sheet metal department, my robotic legs are always ready to support me in any adventure!

Core operations for your electronics.

Talk to elmec’s technicians!

Design and create your custom sheet metal.