Emergency Intercom for the Dubai Metro

Inside train cars, flush-mounted in the body shell.

1 unit per door, 5 cars per train.

Design challenge

In preparation for Expo 2020, we were commissioned to develop an emergency intercom system for the Dubai Metro trains. This complex environmental context – including sand, industrial cleaning, extreme temperature fluctuations, and intensive public use – required high standards in terms of robustness, waterproofing, and long-term durability.

Technical solution

The intercom, intended for indoor use, was designed with a high IP protection rating:

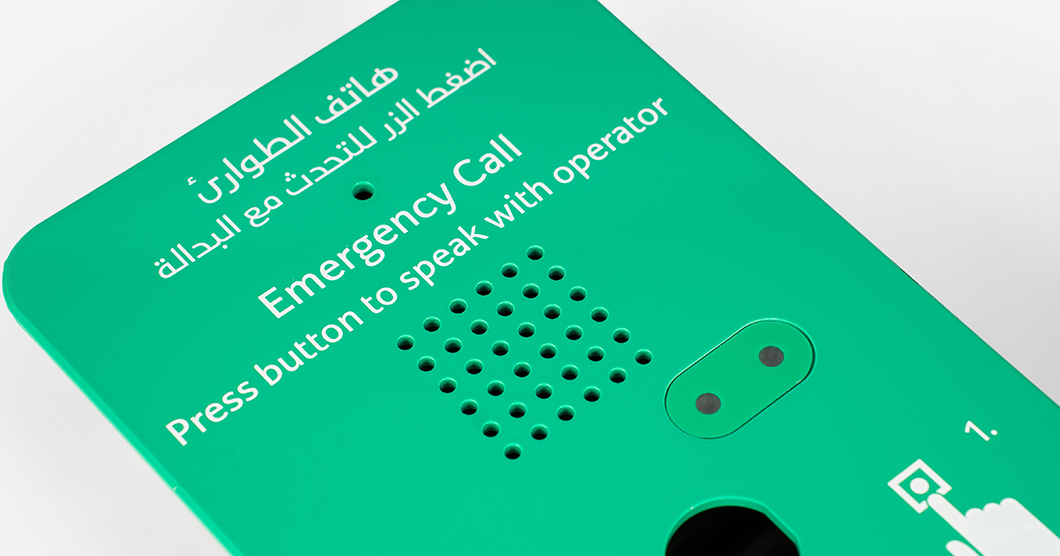

- IP65 front protection, achieved through an internal closure with precision-dosed silicone gasket, ensuring a tight seal between the two halves of the device.

Front-facing components designed to meet the required IP rating:

- Microphone

- Button

- Speaker

- Indicator LED

Structure and materials

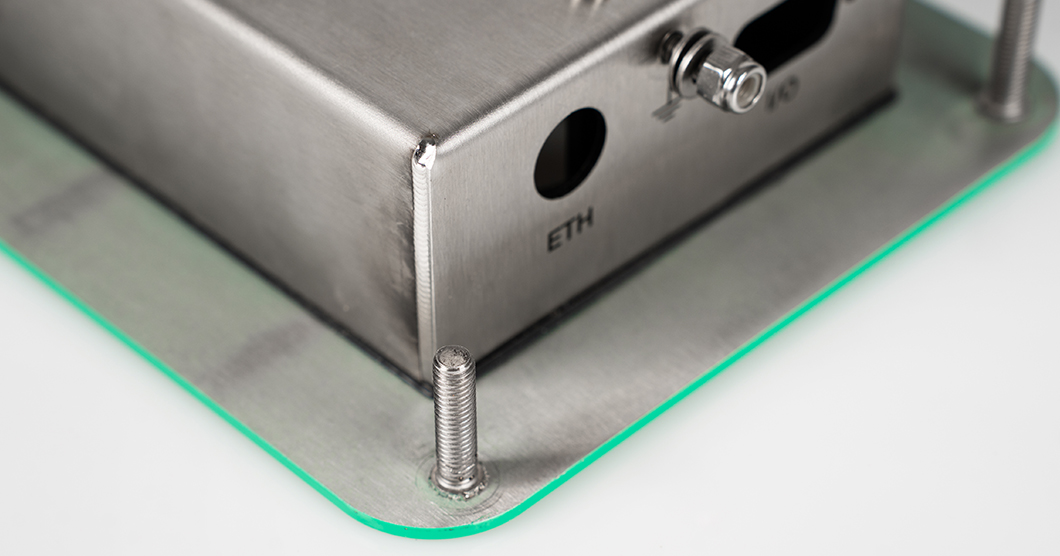

The front panel is made of AISI 304 stainless steel and integrates:

- 4 welded M5x20 studs for wall mounting (a functional choice to prevent tampering and ensure a clean design).

- Additional welded studs for securing the speaker, microphone, and electronic board.

- Light guide.

- Silicone gasket for IP sealing.

The front is finished with acrylic paint that is resistant to industrial detergents, along with screen printing for labeling. The painting process involved two coats:

- The first coat, a white acrylic primer, ensures adhesion to stainless steel.

- The second coat, green in color, aligns with the metro’s visual identity.

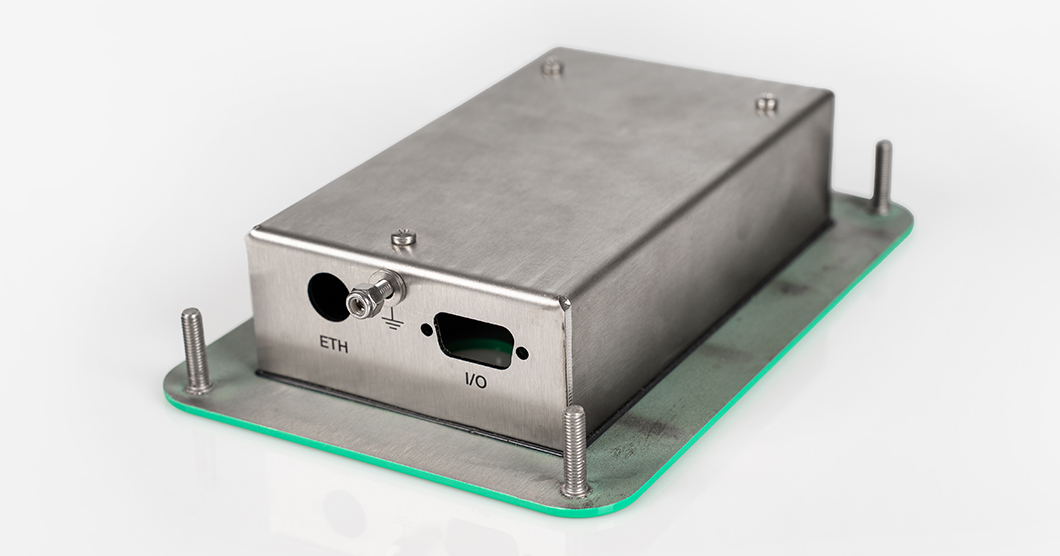

The rear shell is also made of AISI 304 stainless steel, laser welded at the four corners to guarantee proper IP sealing.

Challenges addressed

- Stainless steel processing: precise corner welding and insert application.

- Gasket application: controlled silicone dispensing.

- Painting on smooth surfaces: to ensure adhesion, milled areas were sandblasted to increase surface roughness.

- Adhesive films:

- Adhesive for light guides, applied to ensure IP65 protection.

- Removable protective film with low-residue adhesive, effective even in variable temperatures.

Testing performed

- Cross-cut test performed on 1 painted unit from each production batch to verify paint adhesion.

- 100% torque testing of M5 studs to ensure hold.

- Sample torque testing of M3 studs to ensure performance compliance.

The starting point of your growth.

Do you have a similar product to make?

Ask for support from your expert electronics custodians!