Metal enclosures for electrical panels: what you need to know

When we think of electrical panels and cabinets, the focus often falls on the complexity of their electronics. Yet, another key player is ensuring their optimal performance: the metal enclosure. Often overlooked, it is this mechanical structure that guarantees the efficiency, durability, and safety of the entire system.

Crafted through technical expertise, custom design, and meticulous attention to detail, metal enclosures for electrical panels do much more than simply “house” components — they enhance every aspect of your projects.

What makes an enclosure truly effective for electrical panels and cabinets? And why is elmec the right partner to build it?

What is an electrical panel enclosure, and why is it important?

An enclosure is the mechanical structure that houses and organizes the electrical components of a system. Cabinets, frames, and mounting supports are designed to protect delicate devices while maintaining high performance and shielding them from external agents.

In industrial, civil, and plant engineering sectors, enclosures serve as the critical interface between technology and the surrounding environment. They must perfectly accommodate internal electronics while ensuring organization, accessibility, protection, and operational longevity.

While off-the-shelf solutions might be sufficient in some cases, custom enclosures are increasingly preferred, engineered to meet real, specific needs and to fit your electronics like a tailored suit.

Key features of metal enclosures for electrical panels

A high-quality electrical enclosure is designed to match the demands of the industrial sector in which it will operate — whether automation, HMI, building automation, energy management, or other fields — and to meet the specific requirements of the electronics it protects.

Robustness and durability are essential. Enclosures must provide an adequate IP rating against dust and liquids and withstand impacts, vibrations, humidity, extreme temperatures, and corrosive agents. In industrial or outdoor environments, enclosure strength is what separates a reliable system from a problematic one.

Accessibility and functionality are just as critical. A well-designed structure simplifies installation, maintenance, and inspections. Smart openings, well-arranged internal plates, organized cable routing, and modular layouts make technicians’ work easier and safer.

Customization and compatibility with the housed electronics are the final keys. Dimensions, opening systems, ventilation solutions, cut-outs, and every other detail must align with the equipment’s needs. Only with such precise integration can you achieve optimal, high-performance results.

Choices regarding design, manufacturing processes, materials, and surface finishes directly impact the final performance. The workmanship determines how well the product meets technical requirements; materials ensure compatibility with the operating environment; finishes protect the

structure over time, enhance material properties, or add aesthetic value. A well-considered combination of all these elements results in a solid, truly tailor-made product.

Core components of electrical panel enclosures

Each enclosure incorporates components designed to ensure stability, logical device organization, and practical, efficient interaction with the electronics inside. The most common components include:

- Main enclosures, in monobloc or modular versions, to suit different spaces and configurations.

- Doors and hinges, often with gaskets for IP sealing and built to withstand mechanical wear.

- Internal plates and support brackets, essential for orderly component mounting and system stability.

- Cable entries and trunking systems, facilitating cabling and maintenance.

- Ventilation grilles, improving heat dissipation.

- Mounting and locking systems, ensuring both security and ease of access.

- Other modular and customizable accessories.

These elements, carefully selected and combined, allow the enclosure to evolve alongside your system, providing maximum design flexibility and excellent scalability for future expansions.

The advantages of partnering with elmec

When people ask us what we do best, we prefer to answer with facts and case studies. At elmec, we specialize in manufacturing metal enclosures for electrical panels, cabinets, and equipment that are built to perform, built to last, and built to simplify your daily operations.

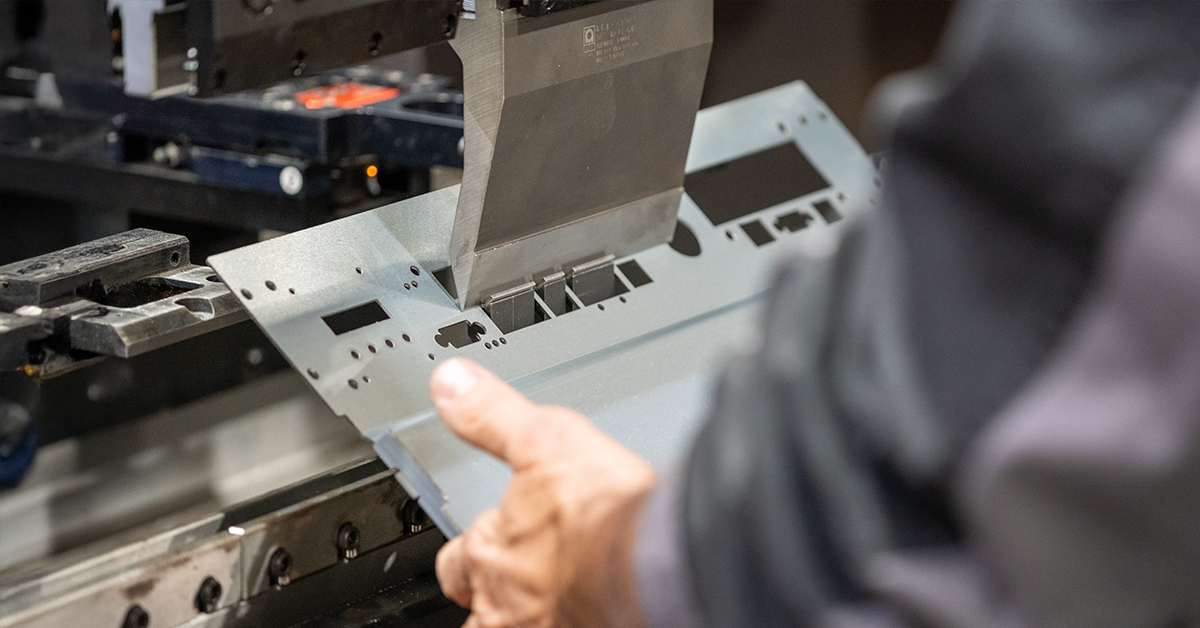

We manage all core production processes in-house: cutting, bending, surface finishing, and CNC milling. When additional capabilities are needed, we rely on a trusted network of external partners with whom we have long-standing collaborations, ensuring complete, integrated solutions.

We manufacture both custom enclosures tailored to your specific needs and standard solutions that immediately address more common requirements. We also provide additional services, including sampling, electronics integration, packaging, and lean production management.

In short, we aim to be the partner who immediately understands your needs and knows exactly how to deliver.

Contact us today to design your next electrical panel enclosure — we’re ready to provide the technical support you’re looking for!