Custom Stainless Steel Processing: Precision Metal Fabrication

In any project involving electronics, the choice of materials and the quality of metal fabrication are crucial factors determining the final product’s success and reliability. Among the various options available, stainless steel stands out as one of the most high-performing materials for the production of electronic enclosures, housings, and custom components.

Its exceptional strength, durability, and suitability for complex processing make it the ideal choice for applications requiring long-term precision and resistance.

At elmec, we’ve been transforming stainless steel into safe, functional solutions for years, designed to integrate seamlessly into your systems and devices. Our expertise in custom stainless steel processing allows us to deliver components that not only meet strict technical specifications but also exceed expectations in terms of performance and longevity.

Why choose stainless steel in electronic and mechanical applications?

Stainless steel is widely recognized for its excellent corrosion resistance—a key property when it comes to protecting sensitive electronics. But its advantages go far beyond that. This material offers a set of characteristics that make it indispensable in many contexts. Such as?

- High dimensional stability and good machinability: Certain stainless steel grades are highly workable, allowing for the creation of complex, precise geometries with minimal deformation.

- Compatibility with precision processes: Ideal for achieving tight tolerances even on thin sheets, enabling the production of extremely accurate components, especially with the right tooling and machinery.

- Resistance to harsh environments: Stainless steel performs excellently in conditions with humidity, aggressive chemicals, high temperatures, thermal shocks, or UV exposure, all while maintaining its mechanical and protective properties.

- Hygiene and cleanability: Its smooth, non-porous surfaces make it particularly suitable for industries with high hygiene standards, such as medical, food, and pharmaceutical sectors.

In the field of mechanical components for electronics, stainless steel is widely used to protect sensitive parts such as electronic boards, modules, actuators, displays, and control systems. Its long-term reliability is especially crucial for outdoor installations or industrial environments with a high presence of contaminants.

From sheet metal to finished enclosure: every step matters

Each project begins with a specific functional need—whether it’s to contain, shield, dissipate heat, or support electronic components. That’s why, at elmec, custom stainless steel processing is never a standardized procedure. We manage every production phase in-house to ensure maximum attention to detail and constant quality control.

What can we offer?

- High-precision laser cutting: We use CO₂ and fiber laser systems to cut complex and detailed shapes, even on small formats and varying thicknesses, optimizing material use and minimizing waste.

- CNC bending: Our latest-generation press brakes perform precision bending with minimal tolerance deviation, ensuring dimensional consistency between the design and the finished product.

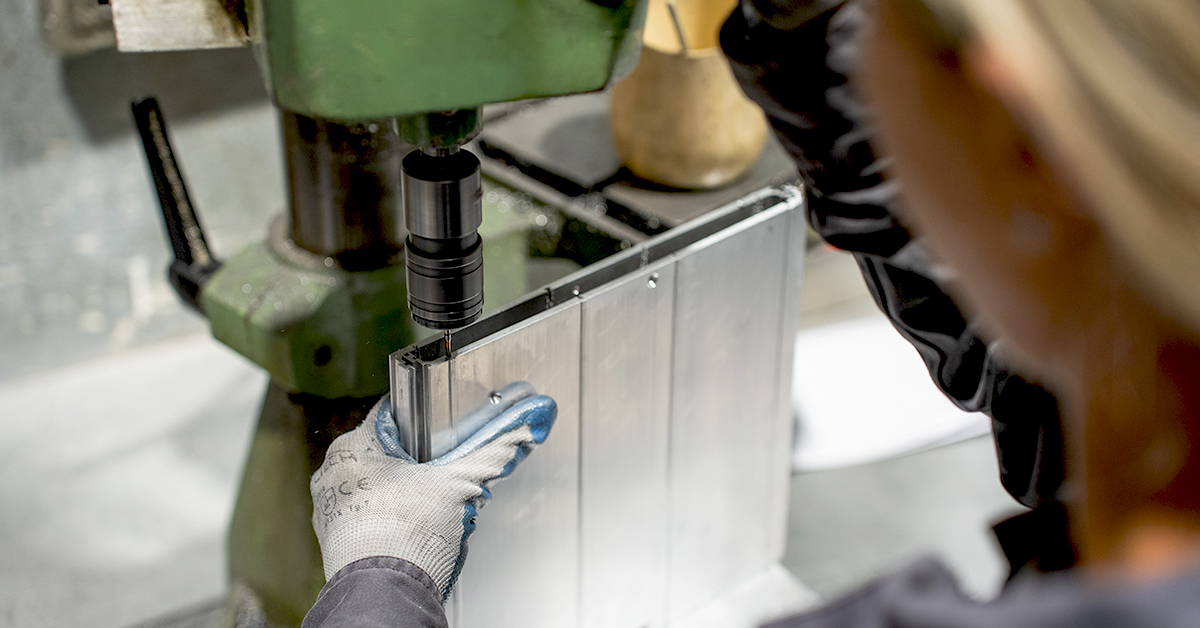

- Punching: Automated punching machines are used to create holes, threading seats, and deformations with high precision. This step is essential to prepare the sheet metal for fastener application and ensure secure, accurate fastening.

- Assembly and integration: We provide in-house mechanical assembly to deliver fully integrated solutions, ready for your production line.

The result? Sturdy yet precisely engineered components and enclosures that interact perfectly with electronic systems.

Surface treatments: when the finish makes the difference

Stainless steel naturally forms a passive chromium oxide layer that provides its intrinsic corrosion resistance. However, in certain circumstances—especially after machining or in highly aggressive environments—specific surface treatments may be needed to restore or enhance this protective layer.

In other cases, targeted finishing treatments are used to:

- Improve adhesion of protective coatings or aesthetic paints, ensuring longer-lasting finishes;

- Achieve specific surface appearances consistent with the product’s design or branding needs;

- Facilitate cleaning and sterilization in medical, food, or pharmaceutical environments where contamination is not an option.

On request, we can handle these treatments with internal resources and a certified network of expert local suppliers. This allows us to maintain full control over quality compliance, ensuring every component meets the highest technical and regulatory standards.

Application examples

The stainless steel solutions we deliver are extremely versatile and serve a wide range of industries. Our customers operate in sectors such as industrial automation, vision systems, HMI, railway transport, home automation, AV and broadcast, and energy management.

In all of these areas, stainless steel offers the perfect combination of mechanical strength, environmental resistance, and mounting precision. We produce shielded enclosures for sensitive modules (essential in automation or broadcasting), rugged HMI housings for industrial environments and vehicles, and support structures for displays and PCBs used in home automation or vision systems.

Our metal fabrication solutions ensure consistent precision and reliability—even with the tightest geometric tolerances—adapting to the needs of each industry.

Beyond stainless steel: other elmec solutions for metal fabrication

While stainless steel is ideal for many applications, our expertise in custom metal fabrication extends across a wide range of materials. For example, we also work with aluminum and its alloys—lightweight and conductive—as well as copper and brass.

We also process aluminized steel, valued for its corrosion and high-temperature resistance, and apply Magnelis® coatings—advanced metallic layers that offer superior protection even in the harshest environments. Our ability to handle multiple materials allows us to always recommend the best solution for each project.

Partnering with elmec: a technical, tailored approach

Choosing elmec means partnering with a team fluent in the language of mechanical engineering for electronics. We don’t just manufacture metal parts—we develop integrated solutions based on specific application needs, collaborating closely with your technical team from start to finish.

Our mission is to transform your vision into a fully optimized, functional product. You can count on:

- Custom in-house design, starting from a drawing, a physical sample, or even just an idea, to develop the most effective, innovative solution;

- Ongoing technical support, from prototyping to series production, offering guidance and solving critical challenges;

- Full process management, from material selection to final treatment, even for small batches and highly complex components;

- Rigorous quality control and traceability, with every job tracked and validated through a structured system that ensures full compliance.

Whether you need a fast prototype, a small high-precision batch, or a long-term supply solution for your production lines, we help you achieve a concrete result, ready to be integrated into your product or system.

Our stainless steel processing expertise is at your service: get in touch for a personalized technical consultation on your next project.