Custom metal enclosures for electronics: protection and thermal management

Designing metal enclosures for electronic equipment means finding the right balance between protection against external agents and effective thermal management. Simply enclosing components is not enough: an engineered solution is required to ensure reliable performance, regulatory compliance and optimal integration with the electronics.

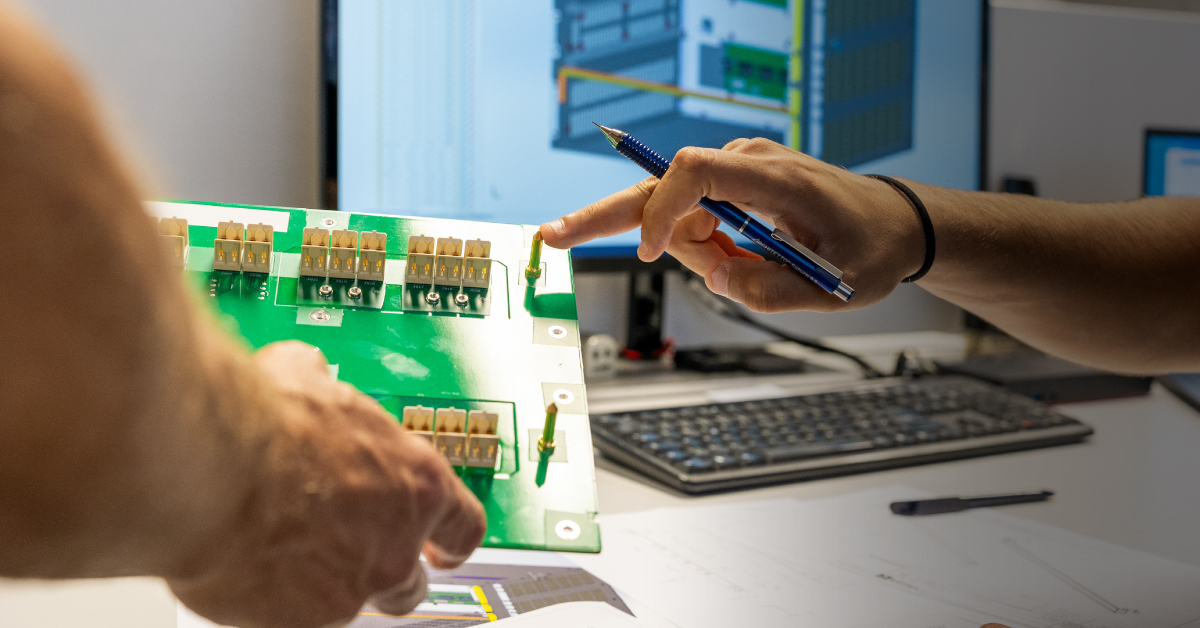

For electronic device manufacturers, system integrators and companies developing IoT solutions, industrial automation or HMI systems, the choice of enclosure directly affects product lifespan, operational safety and market competitiveness. At elmec, we manufacture custom metal housings that combine precision CNC machining, certified materials and advanced technical finishes, providing your electronics with the protection they deserve.

Why choose custom metal enclosures

Standard enclosures available on the market are designed for general needs: fixed dimensions, limited protection ratings and rigid internal configurations. When a project requires precise technical specifications, these compromises can lead to integration issues, component overheating, assembly difficulties or inadequate performance in the operating environment.

A custom metal enclosure is developed starting from real application requirements: optimized dimensions, appropriate IP rating, engineered ventilation, and materials selected for thermal conductivity and mechanical strength. Every detail is designed to enhance the electronics and simplify the work of those who integrate, assemble and maintain them over time.

For electronics manufacturers, this approach also means reducing time-to-market: an enclosure designed together with the device eliminates subsequent modifications, accelerates validation testing and improves the perceived quality of the finished product.

IP protection: choosing the right rating for the application

The IP (Ingress Protection) rating defines the enclosure’s resistance to dust, liquids and accidental contact. Selecting the correct IP rating is essential to ensure reliability and regulatory compliance.

IP54 and IP65: protection against dust and water jets

IP54 housings provide protection against dust and water splashes, making them suitable for indoor industrial environments or protected applications.

IP65 ensures complete protection against dust and resistance to water jets from any direction, making it ideal for devices installed in production areas, warehouses or partially sheltered outdoor environments.

IP66 and IP67: maximum protection for critical environments

IP67 guarantees total protection against dust and temporary immersion in water up to 1 meter in depth.

IP66, on the other hand, ensures protection against powerful water jets and is suitable for process plants or marine installations.

At elmec, we manufacture enclosures compliant with different IP classes through precise mechanical machining, certified gaskets and closure systems designed to maintain sealing performance over time. Each enclosure is tested and documented to ensure declared compliance.

Thermal management: handling heat in metal enclosures

Electronic components generate heat, and inadequate dissipation can lead to malfunctions, reduced performance or premature failures. Thermal management in a metal enclosure depends on several design and construction factors.

Material selection and optimal thickness

Aluminium offers excellent thermal conductivity and low weight, making it particularly suitable for heat dissipation by conduction when integrated into a properly engineered thermal design of the enclosure.

Stainless steel, while having lower thermal conductivity, provides superior robustness and corrosion resistance. The choice depends on the application: stainless steel is preferred in critical outdoor environments, while aluminium is ideal where weight reduction and thermal performance are priorities.

Integrated ventilation systems

Strategically positioned ventilation grilles promote natural air circulation, reducing internal temperature without active components, when compatible with the IP protection rating required by the application.

Vent opening design must still preserve the required IP rating: we use grilles with dust filters and engineered designs that prevent liquid ingress, ensuring protection and ventilation at the same time.

Finned surfaces and integrated heat sinks

For applications with high heat generation, we can integrate finned surfaces or heat sinks directly into the enclosure structure, increasing the heat exchange surface and improving passive thermal dissipation efficiency under the operating conditions defined by the project.

Surface treatments for thermal control

Surface finishes influence the thermal emissivity of metals. Aluminium anodizing, for example, improves heat dissipation by radiation. Specific coatings can be selected to optimize thermal properties without compromising corrosion protection.

Designing the enclosure as an active system

Effective heat management starts with mechanical enclosure design, not with fans or heat sinks added later.

Preliminary thermal analysis

Before defining geometries and materials, we evaluate dissipated power, critical heat-generation points and maximum operating temperatures. This allows correct dimensioning of thicknesses, heat exchange surfaces and natural ventilation systems.

Geometries optimized for convection

Inclined walls, geometries that promote upward airflow and strategic positioning of openings: every detail affects natural convection efficiency. Our CNC machining capabilities enable the production of optimized profiles that maximize heat exchange surfaces.

PCB-to-enclosure thermal coupling

For critical thermal loads, we design mounting interfaces that ensure effective and controlled thermal contact between heat-generating components and metal enclosure walls. The use of thermal interface materials and intermediate plates efficiently transfers heat to the outside.

Integrated forced ventilation

When natural convection is not sufficient, we integrate provisions for fans with dust filters, compatibly with the IP rating required by the project. Grilles are designed to maximize airflow while minimizing contaminant ingress.

Surface finishes for performance and durability

Surface treatments are not merely aesthetic: they directly affect corrosion resistance, electrical properties, thermal dissipation and regulatory compliance.

Anodizing for aluminium

Anodizing creates a protective oxide layer that increases abrasion and corrosion resistance, improves electrical insulation and enhances thermal dissipation. Available in different colors, it also enables aesthetic customization consistent with product identity.

Passivation for stainless steel

Passivation restores the natural protective layer of stainless steel after machining, ensuring maximum corrosion resistance. It is a key treatment for enclosures intended for critical environments or outdoor applications.

Galvanizing and powder coating

For carbon steel, galvanizing provides an effective corrosion barrier. Powder coating adds further protection, visual uniformity and color customization, while maintaining high mechanical and chemical resistance.

Nickel plating for conductivity and protection

Chemical or electrolytic nickel plating improves wear resistance and chemical durability while maintaining good electrical conductivity. It is particularly suitable for enclosures requiring EMI shielding in combination with proper EMC design, or reliable electrical contacts.

Industry 4.0 and incentives: opportunities to innovate

In recent months, many electronics-sector companies have leveraged Industry 4.0 incentives to upgrade production lines or develop new interconnected products. These projects often require advanced metal enclosures with specific features for integrating sensors, monitoring systems and data communication.

Custom elmec enclosures can integrate:

- IoT sensor provisions: holes, cable glands and supports designed to house environmental, vibration and temperature monitoring devices

- EMI/RFI shielding: to protect electronics from electromagnetic interference in complex industrial environments

- Quick-mounting systems: to simplify maintenance and technical interventions, reducing machine downtime

- Permanent labeling and marking: QR codes, serial numbers or technical information directly marked on the enclosure for Industry 4.0 traceability

The ability to customize every aspect of the enclosure allows companies to maximize technology investments and deliver innovative solutions that stand out in the market.

Choose elmec for your custom metal enclosures

Whether you need to develop a housing for a new IoT device, an IP67 enclosure for outdoor applications or an integrated solution for an industrial automation system, elmec is a technical partner capable of turning your requirements into concrete solutions.

From metal fabrication to custom electronic enclosures, we develop products that protect, last and integrate seamlessly with your electronics.

Ready to design your next custom metal enclosure?

Contact us for a technical consultation: we will analyze your needs together and propose the most effective solution for your project.