Aluminized Steel: Features and Processing

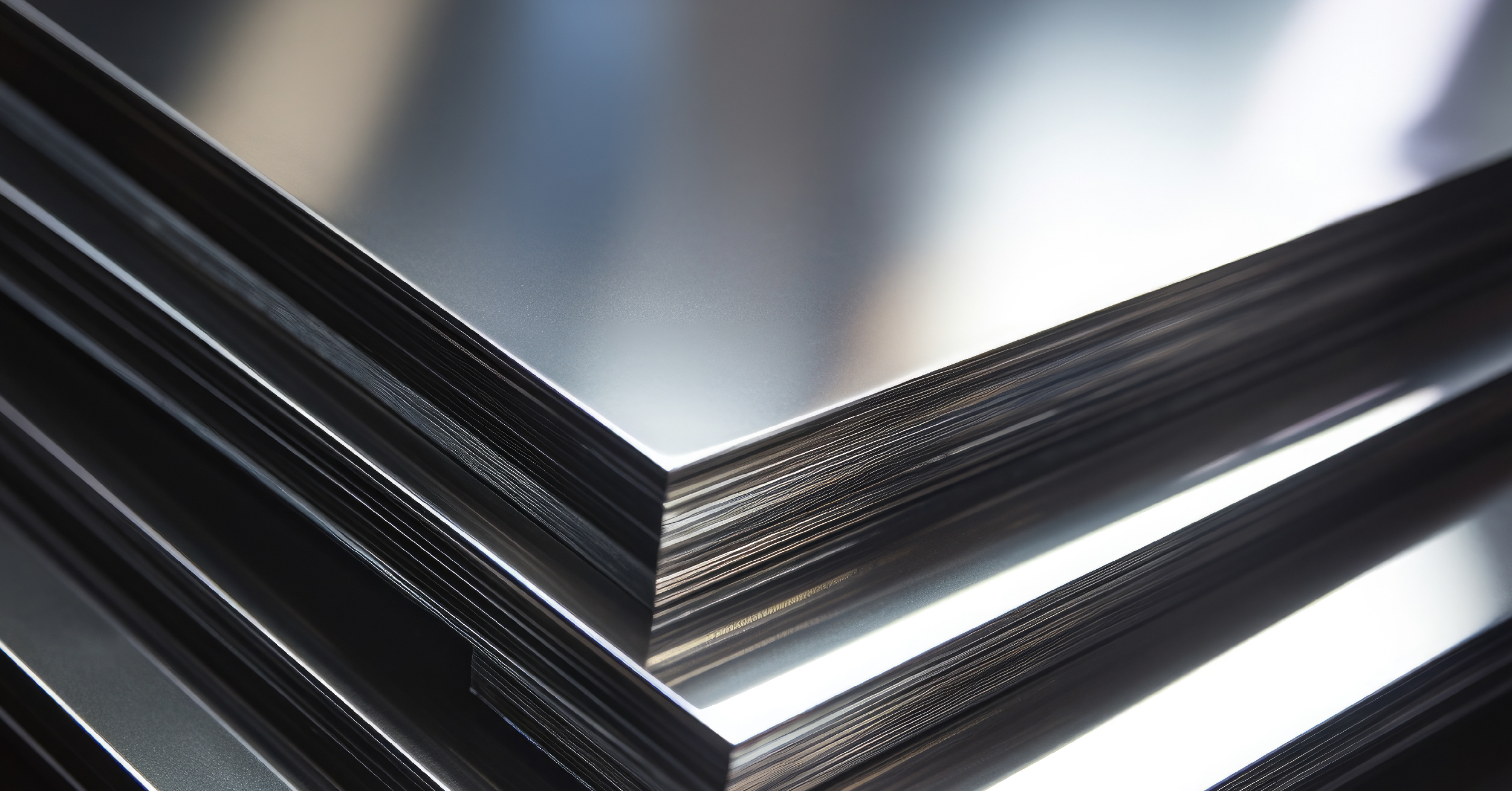

In the world of mechanical engineering for electronics, the choice of materials plays a crucial role in ensuring the longevity, strength, and robustness of your projects. One of the most innovative and high-performing materials that Elmec has introduced into its production processes is aluminized steel. This material combines the strength of steel with the oxidation protection of aluminum, making it perfect for applications where resistance and lightness are essential.

What is aluminized steel and why is it important for your projects?

Aluminized steel consists of a steel substrate coated with an alloy of aluminum (90%) and silicon (10%), applied through a continuous hot-dip process. This treatment endows the material with unique characteristics that make it ideal for particularly challenging environments, where protection against corrosion, heat, and other forms of external stress is essential.

Advantages of aluminized steel: why choose it?

- Corrosion resistance: The aluminum coating acts as a barrier against corrosive agents, protecting the underlying steel. This makes aluminized steel ideal for humid environments or those containing aggressive agents such as chemicals or salts.

- Heat resistance: Aluminized steel maintains its mechanical properties even in extreme temperature conditions, offering superior thermal resistance compared to many other materials used in mechanical engineering for electronics.

- Lightness and strength: While maintaining a robust and impact-resistant structure, aluminized steel is lighter than other alloys due to its aluminum coating. This makes it particularly suitable for projects where lightness is a key factor without compromising strength.

- Coating adhesion: The hot-dip process ensures optimal adhesion of the coating, preventing issues like chipping or delamination, ensuring that the coating remains intact even in harsh conditions.

Applications of aluminized steel in the electronics industry

In the field of mechanical engineering for electronics, aluminized steel is widely used to manufacture cases and structures for electronic equipment, designed to operate in environments with a high risk of corrosion or extreme thermal conditions. Its distinctive properties make it especially suitable for applications that require long-lasting and secure protection.

Thanks to its reduced weight, resistance, and flexibility, aluminized steel is ideal for protecting electronic devices used in industrial environments, such as robotics and automation, where components must withstand continuous mechanical stress and high temperatures. Additionally, its characteristics make it optimal for constructing mechanical structures that require constant heat dissipation.

Comparison between aluminized steel, Aluzinc, and Magnelis®: what sets them apart?

Besides aluminized steel, other high-quality materials are often used in the field of mechanical engineering for electronics, such as Aluzinc and Magnelis®. But what are the main differences?

- Magnelis® is an alloy that combines zinc, aluminum, and magnesium, offering particularly high corrosion resistance thanks to its self-healing capabilities: magnesium helps repair small surface scratches, protecting the underlying substrate.

- Aluzinc, on the other hand, consists of a combination of aluminum, zinc, and silicon and also offers excellent corrosion resistance, though without the self-healing properties of Magnelis®.

While aluminized steel excels in applications that require high resistance to heat and excellent corrosion protection, Aluzinc and Magnelis® are particularly suited for specific situations that require protection from highly aggressive atmospheric agents.

Why choose Elmec as your partner for processing?

At Elmec, we have extensive experience in processing materials for mechanics applied to electronics. Thanks to our deep knowledge of materials and production processes, we can help you choose the best solution for your needs. Our team of specialized technicians will guide you in selecting the most suitable material and in designing your mechanical devices, always ensuring maximum efficiency and functionality.

Discover all our processing options for aluminized steel

Trust Elmec to create durable, custom mechanical cases and structures. Our processes include cutting, bending, satin finishing, deburring, and applying fasteners, all integrated into a production ecosystem that includes core processes such as extrusion and solid metalworking. We also collaborate with a network of reliable local partners to offer you high-quality surface finishes and additional processing tailored to your needs.

Contact us today to discuss your next project and discover how we can help you enhance the resistance, functionality, and durability of your electronic devices with aluminized steel!

Elmec – Combining mechanical expertise and electronic innovation for your projects!