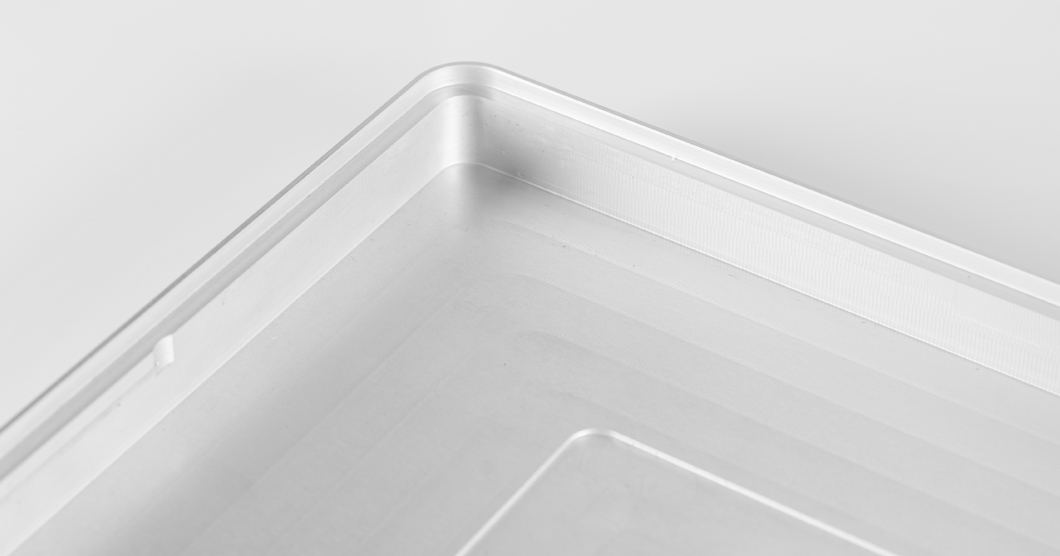

Unibody Case for HMI Interface

The product is a unibody case that can accommodate a fully recessed multitouch display with its power and control electronics.

Requirements of the product

The initial requirements for product development were:

- Maximum surface flatness for a correct recessed installation of all electronics

- High aesthetic performance of visible painted surfaces

- Realization of internal areas without paint for contact with elements with need of dissipation

- Free pass online introduction

The frame is part of a range of sizes from 5″ to 21″ designed as industrial HMI, which can be installed directly in line thanks to a range of brackets, without cabinet, thanks to the degree of protection IP67.

Material selection

Material selection has been crucial in ensuring mechanical and aesthetic requirements. A flat product with thicknesses from 15 to 30 mm can be obtained mainly from 3 production processes:

- Rolling

- Extrusion

- Merger

The choice was dictated by the crossing of several factors:

- Guarantee of flatness before and after milling operations

- Highest aesthetic grade after powder coating

- Commercially available formats suitable for the purpose

- Better cost compromise

Extruded 6082 aluminum was chosen for smaller sizes, such as 5, 7, 10 and 15 inches, and laminated 5083 for the larger 21-inch size. The plates, cut to size, are completely emptied by milling carried out thanks to mechanical brackets on the worktops. The back side of the case is then reworked by mechanical satin-plating to eliminate all possible residues of tool passage in order to make the surface aesthetically uniform to the subsequent powder coating.

Surface treatment

To ensure a flawless and durable finish, specific treatments have been implemented. Before painting, the product is treated with a SURTEC 650 chrome plating that can clean the product and create an ideal condition for adhesion.

As a rule, this type of passage would not be necessary before a powder coating, but in this case it is carried out with the dual purpose of highlighting any surface defects not visible on the raw work piece, intercepting anything that could interfere with the post paint result.

The blind threaded holes are cleaned by injections of perchloroethylene, able to dissolve and evacuate any residues of processing oils and chips that would make the thread not fully functional. The painting is carried out with high-end ad-hoc selected powders with a degree of impurity inclusions as low as possible.

The goal was to achieve a paint thickness of between 40 and 200 microns as uniform as possible on all surfaces. A greater thickness, would involve accumulations of dust with consequent aesthetic distortions also given by the increased probability of inclusions, as well as the need to protect the threads before its application.

A lower thickness would make it difficult to effectively cover surfaces and machining marks, as well as the impossibility of laser marking machine data without discovering the metal. The achievement of this balance was also achieved thanks to the study and use of frames made ad-hoc able to balance and manage the electrostatic effect that distributes dust on surfaces.

The products must be at the right distance and with the appropriate inclinations when hooked on the frames to avoid mutual contamination. Products with masses and surfaces that are too different from each other, when painted at the same time, can give rise to not excellent quality implications.

Quality controls

One of the basic requirements for this type of product was to be able to introduce them in the assembly line of electronics without further checks. The display is glued and sealed inside the case, making it in fact not removable in case of malfunction or aesthetic defect.

It was therefore necessary to introduce 100% controls throughout the production process. Specifically, 100% visual checks are made in 3 different steps before and after painting. The final inspection is carried out with the aid of graduated optical magnification instruments able to measure the extent of any imperfections present and assess compliance with the specifications drawn up 4 hands with the customer.

The products, along the entire production process, are handled with single cartene packaging to prevent the occurrence of defects and in particular ensure that there are no contamination with the painted layer. Core technologies: extruded profile cutting, milling, satin cutting, thread protection. Technologies of our production ecosystem: SURTEC 650 chromatization, powder coating.

The starting point of your growth.

Do you have a similar product to make?

Ask for support from your expert electronics custodians!